Transcription

National Geographic - Making an Artificial Eye

Did you know that the average human eyeball is two-and-a-half centimeters wide, by two-and-a-half centimeters deep, by a fraction over two centimeters tall? No, that’s not the kind of information you gonna need every day. Unless, of course, you make them for a living.

This medical laboratory has been producing artificial eye since World War I. Back then, they were known as The Army Spectacle Depot, but they’ve come a long way since then. Now they look after over 40,000 patients and they make over 6,000 eyes a year.

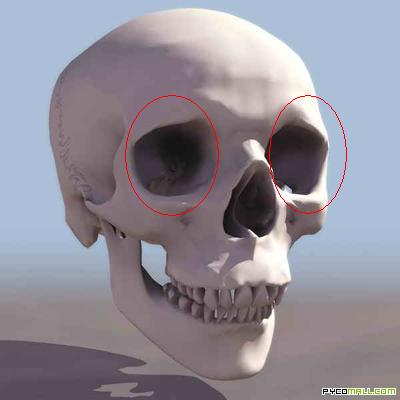

Every single eye is made by hand to an exact order. A wax pattern of the patient’s eye socket is set here, to the lab in Blackpool, and a plaster of Paris casts is made. This produces a mold that is the exact shape of the eye that they are going to manufacture.

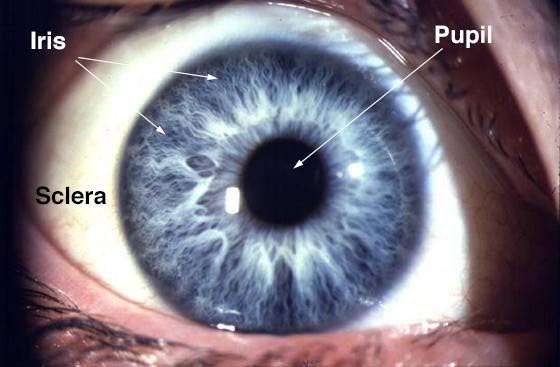

The iris or color part of the eye is painted onto a flat plastic disc, which is measured to the size of the patient’s remaining iris. Each iris is hand-painted using oil-based paints, and the technicians work from either a digital photic or a previously painted eye to make sure that it will match the other eye.

After 18 hours, the iris paint is dried and it get pressed into a bottom-shape-disk. This put a curve on the top of the iris, so that it would be flush on top of the round eye. The iris is placed up-side-down in a mold and the white of the eye is made. It’s made out of polymethyl methacrylate, a medical graded acrylic plastic, similar to the material that used to make false teeth. Once prepared, it squashed down into the cast of the top of the iris, and the whole mold goes into the oven for two-and-a-half hours.

The eye is now starting to take shape, the excess acrylic material is trimmed away on a grinding wheel, and the eye gets stained and veined. The average human eye isn’t snow white, so a bit of water color paint is dapped around the edges, depending on the patient’s natural color.

This embroidery silk is used to replicate the veins of the eye; the thread is separated into individual fibers and applied with an acrylic varnish. Just one centimeter of this thread will provide enough fibers to make over one hundred eyes. A coat of clear acrylic varnish is applied over the top of the eye and it gets oven cure to seal it. Finally a buff and polish gives it a nice glossy finish and the appearance of a living eye.

The expected life span of an artificial eye is around six years, as long as it gets to look after properly. And the end result is pretty amazing. Met Pravel! He’s been wearing an artificial eye since an accident when he was fifteen. Can you tell which one it is? Are you looking hard? Nope, I can’t tell either. Okay, it’s actually the one on the right of the frame. Thanks, Prav!